Plinth 1

Time clock, about 1910

This time clock was used to record the start and end time for employees working at John Readhead & Sons Ltd. Timekeeping was strictly monitored in the yards and workers would have their pay docked if they were late, or sometimes even sent home with no pay.

This type of time clock is known as a dial recorder. Instead of using individual time cards inserted in a slot, this example worked by moving a pointer at the end of a centrally pivoted arm to a hole beside the employee’s works number and then punching. A roll of paper inside the machine recorded the arrival and departure times of each worker. The information from the printed paper roll would be used by a wages clerk to calculate each employee’s pay at the end of the week.

Loan: South Tyneside Libraries

***

Case 1

Handbooks, 1930s-1960s

The illustrations on the front covers of these handbooks issued by South Shields County Borough Council, Jarrow Borough Council and Hebburn Urban District Council show just how important shipping and the industries of shipbuilding and ship repair were to these localities and their inhabitants. Although shipbuilding ceased at Jarrow in the early 1930s, ship repair remained an important employer in the town, and the handbook issued by Jarrow Borough Council also features an advertisement for the ship repair firm Palmers Hebburn Co. Ltd. on the back cover.

TWCMS : 2010.4541, 2016.673, 2022.80

***

Time card, 1998

Many shipyard tradesmen and apprentices started work at 7:30 am. Timekeeping was strictly monitored and workers would have their pay docked if they were late, or sometimes even sent home with no pay. Time cards were used to record when an employee ‘clocked-in’ (began their shift) and ‘clocked-out’ (finished their shift). At the start and end of their shifts, workers would insert their time card into a slot on the time clock, and the machine would print the date and time on the card. Sometimes workers would try to beat the system, by clocking in/out their friends as well as themselves.

This time card was kept by caulker/burner Eddie Pippin as it was from his last shift before retiring. Eddie served his time at Brigham & Cowan Ltd., working his way up to be Foreman Ironman.

Loan: Eddie Pippin

***

Cartoon, 1970s

In this cartoon by Harry Bennet, the Gate Man at Brigham & Cowans of South Shields, a rather unexpected delivery has been received at the General Store. Depicted on the left, wearing his trademark trilby hat, is the Stores Manager Bob Fowler.

Countless young apprentices were sent to the general store for an imaginary commodity in their first days on the job, the most common to be sent for a “long stand”. The apprentice, still wet behind the ears, would be told to “stand there” and would patiently wait for the storekeeper to fetch the item he’d been sent for, which would of course never come. Others were the key to the dock gates, the golden rivet, a sky hook…can you recall any more?!

TWCMS : 2022.92

***

Cartoons, 1977 and 1997

Shipbuilding and ship repair yards were dangerous places to work where injuries and sadly also fatalities were all too common. They could also be unpleasant workplaces, particularly in ship repair; few would say they enjoyed working in a cold, slimy dock bottom in mid-winter – sometimes even in the snow – or crawling through black sludge in the confined space of a ship’s double bottom.

Humour was an important way to get through the day, helping to counteract the hazards, unpleasantness or just plain monotony.

“I hear you Foremen are going to have a Whipround for Bob Fowler!” The cartoonist is Harry Bennet, who was the Gate Man at Brigham & Cowan Ltd., South Shields. The subject is the retirement in December 1977 of Bob Fowler, the joke being that the chap with the bullwhip (perhaps supposed to be the Yard Manager) has clearly got the wrong end of the stick!

Reflecting on his time working at the Mercantile Dry Dock Co. Ltd. in Jarrow in the 1970s, Brian Leithead drew the “Shipyard jobs in Jeopardy” cartoon in 1997. Two Mercantile Dry Dock workers, wearing overalls and flat caps, are standing in front of a Thompson’s Television shop window display. A TV in the window announces “News flash! Shipyard Jobs in Jeopardy”. The worker on the left thinks that ‘Jeopardy’ must be the location of a foreign shipyard, where there are jobs!

TWCMS : 2022.96, 2022.215

***

Joiners’ tools, 1950s

Edwin Scott was apprenticed as a joiner at Middle Docks, South Shields, in the 1950s. He bought these tools – a jack plane and a smoothing plane – from the ironmongers Frank Lake & Sons of Fowler Street, South Shields, and stamped them with his name, “E.W. Scott”. The original receipts from Frank Lake, and the stamp used by Edwin to mark his tools as his own, are also shown here.

Loan: Edwin Scott

***

Case 1 – shelf

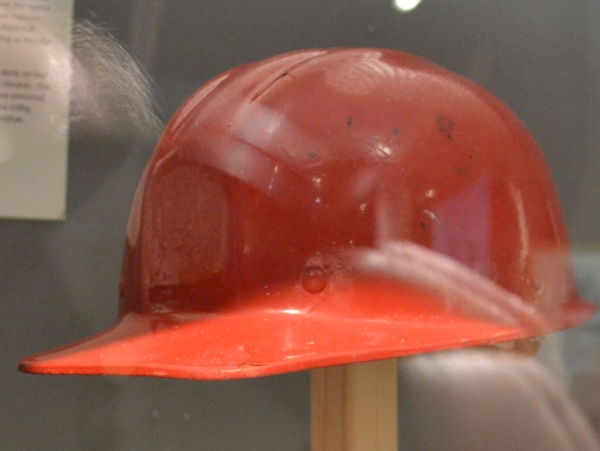

Shipyard headwear

Up to the 1960s, most shipyard workers wore a flat cap. Trilbies or bowler hats were worn by foremen to signify their position of authority. None of these provided any actual protection to the head though, and many head injuries sadly resulted in a fatality. It wasn’t until the 1970s that widespread wearing of hard hats came about. Different colours were issued to indicate roles and responsibilities. The red hard hat displayed here was used by joiner Edwin Scott while working at Middle Docks, South Shields, in the late 1970s – early 1980s.

The black and white photograph shows shipwrights laying deck on the forecastle of a ship in the 1950s at Readheads Dock, South Shields. The men in the foreground are all wearing flat caps. Two of those pictured are Freddy Colthorpe and Bobby Dunn. The man wearing the trilby, standing in the background, is Foreman Shipwright Jack Mordue.

TWCMS : H3933, 2008.2076, 2017.2144, 2022.159

Loan: Edwin Scott

***

Billy can, mid-20th century

Billy cans were used to make tea in the shipyards. The lid doubled as a cup. This one was owned by Freddy Laing who served his time at Palmers Hebburn Co. before going on to work most of his life at Middle Docks in South Shields.

The photo shows Hawthorn Leslie electricians Billy McCullough and Harry McDough on their dinner hour, reading newspapers in the sun, in about the late 1950s. A billy can sits beside Harry, on the right.

TWCMS : 2008.326

***

Model of “screw propeller”

(Forerunner of the modern ship’s propeller)

Invented by the late Mr. George Rennoldson, of South Shields.

The propellers were worked by men standing in the well of the deck, and turning the crank handles attached to the shaft or spindle of the wheel. The first boat fitted with these propellers made its first trip up the River Tyne in 1821 or 1822.

TWCMS : 2022.210

***

Plinth 2

Cot, 1942

This baby’s cot was made using timber salvaged from the Royal Navy destroyer HMS Kelly. One of South Tyneside’s most famous warships, HMS Kelly was built at Hawthorn Leslie’s Hebburn shipbuilding yard in 1939. She suffered a turbulent start to her career, surviving damage from sea mines, a collision with HMS Gurkha and, in May 1940, attack from E- boats and bombers in the Battle of Norway.

It was during a return visit to Hebburn for repairs that local man Joe Grant salvaged the wood for the cot. The Kelly’s luck finally ran out in 1941 when she was sunk in the Mediterranean during the evacuation of Crete. The following year Joe used the wood to make a cot for his first grandchild, Jim.

Look out for a model of HMS Kelly as well as Kelly’s original ship’s bell, which can also be seen in this exhibition.

TWCMS : 2010.3314

***

Case 2 – base

Programme and presentation address, 1920

Prince Albert (later King George VI) visited the dry docks and works of The Middle Docks & Engineering Co. Ltd., South Shields, on 16 April 1920, while on a two day visit to Tyneside. Earlier in the day the Prince had also visited Readheads shipyard, marine engine works and docks.

At Middle Docks, over 200 ex-servicemen in the Company’s employ lined the dockside at No. 3 dock to welcome the esteemed visitor. Prince Albert was introduced to three workmen with the longest service: Carpenters W. Whittles (53 years) and T. Tully (48 years) and blacksmith A. Scott (37 years), and he also inspected the Middle Docks Cadet Corps on the north side of the new No. 4 dock (opened 1917).

On the day of the Royal Visit, there were no fewer than 11 vessels either in the Company’s docks or moored alongside the quay wall, a newspaper report commenting that the Prince saw “a veritable hive of industry in full swing”.

TWCMS : P1352, 2019.384, 2022.221

***

Decorated launch bottle, 2022

A bottle of champagne is traditionally smashed against the bow of a ship at its launch ceremony. Queen Victoria is believed to have popularised the use of champagne when she launched HMS Royal Arthur in 1891. Prior to this, a bottle of red wine was generally the order of the day. In Prohibition era America, a bottle of water was used. There have been occasions when whisky was used and in November 1945, when painter’s labourer Mrs. Margaret Lee launched the SS Obra at Readheads yard in South Shields, a bottle of cider was swung against its bows.

Launch bottles were gaily decorated using red, white and blue ribbons. At Hawthorn Leslies in Hebburn, it was the job of the Head Tracer to decorate the bottles. This one has been recreated based on archive photos from ship launches in the museum’s collection.

TWAM / Alex Thirlaway

***

Lightbulb

Let there be light! Electric light first came to South Shields on 22 January 1879 when H.S. Edwards & Sons experimented with the new technology at their High Docks (later part of Readhead’s yard). A report from the Shields Gazette the following day stated: “A bright light was thrown over the whole of the dock and a pin might have been discerned upon the ground with the same ease as if it had been daylight. Many persons unaware of the experiment rushed to the place, believing a fire had broken out”.

TWCMS : 2009.2310

***

Launch photograph, 1930

Launch day was a special day of celebration at shipbuilding yards, when after many months of hard work the hull of a new vessel was ready to take to the water for the very first time. New ships were launched by a ‘sponsor’, the name given to the person (usually a woman, such as the wife of the shipowner or a member of the aristocracy) who had the special task of naming the vessel and wishing her and those who sailed in her good luck. The sponsor would swing a bottle to break against the ship’s bow and then, as if by magic, it slid gracefully down the ways – thanks not to magic but to the actions, unseen by the dignitaries on the launch platform, of the yard’s shipwrights.

The sepia photograph is of a Mrs Stobart poised to launch Yard No. 574, the collier Pinewood, at Hawthorn Leslie’s Hebburn Shipbuilding Yard on 14 April 1930. Pinewood’s career was cut short on 3 January 1941 when she sank after hitting a mine off Southend, while on a voyage from London to Blyth in ballast.

TWCMS : 2016.390

***

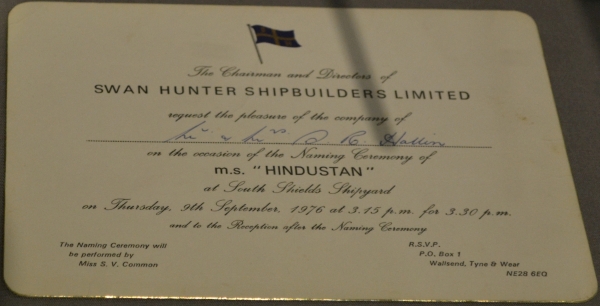

Ship launch invitations, 1976-1979

Swan Hunter Shipbuilders Ltd., South Shields Shipyard (formerly Readheads) and Hebburn Shipyard (formerly Hawthorn Leslies)

Robsons Boat Builders Ltd., South Shields

Two of these invitations were issued to Stanley Hollin, who was the Purchasing Manager at Swan Hunter Shipbuilders when the Tyneside shipbuilding consortium became part of British Shipbuilders Corporation in 1977. Stanley became a Director of British Shipbuilders, retiring in 1986.

TWCMS : 2015.1351, 2015.1364

Loan: Rebecca Brown

***

Bottle of champagne, 1966

This bottle of Mumm Cordon Rouge champagne came from Readheads shipyard. It would have been bought for a ship launch at the South Shields yard, but was instead brought home (presumably with permission!) by Readheads employee Thomas Hastie, and has remained unopened for 56 years.

Thomas’ daughter Susan recalls, “My father was Office Manager at Readheads and was responsible for helping to organise the launches of new ships. I can remember my mother making rosettes with red, white and blue ribbons which would be tied to the bottle of champagne to be smashed against the side of the ship by the guest dignitary. The bottle had to be scored down the side to make sure it shattered on impact, as it was considered bad luck if the glass didn’t break when the ship was launched.”

Loan: Susan Dibden

***

Case 2 – shelf

Rivet and rivet catcher’s tongs, early to mid-20th century

Rivets held together the plates and frames of iron and steel ships, before the advent of welding in the twentieth century. Riveting was a very laborious and noisy process. Riveters worked in squads of five: a ‘heater’, a ‘catcher’, a ‘holder-up’ and a pair of ‘riveters’.

This rivet came from North Sands Shipyard in Sunderland. The heater’s tongs were used at Readheads yard in South Shields.

Loan: Bob Gallagher & Dr. Paul Stott

***

Clock and invitation card, 1949-1950

Shipbuilding and ship repair had a long history on the site of Middle Docks, South Shields, with mention of the yard stretching back at least as far as 1772.

In 1899 what had been known as the Middle Dock Co. was sold and a new company Middle Docks & Engineering Co. Ltd. was formed, with Mr. J.H. Edwards at its head. His son, Sir Lawrence Edwards (1896-1968) took over as Chairman and Managing Director, upon the death of his father in 1945.

In 1949 the firm, in its then present incarnation, celebrated 50 years in business. A special golden jubilee dinner was held at the Hedworth Hall on 1 February 1950, and the invitation card displayed was issued to a Mr. T.B. Ford. The oak mantel clock bears a small plaque inscribed with: “A. Addison, The Middle Docks & Eng. Co. Ltd., Jubilee Commemoration, 1899-1949′.

T.B. Ford and A. Addison were presumably employees, but we would love to know more about them…can you help?

TWCMS : 2014.249, 2017.2269

***

Model of lifeboat Tom Perry, about 1872

The Tom Perry was built for the Tyne Lifeboat Institution in 1872 as a replacement for the lifeboat Providence of 1845. Tom Perry was built by James Jackson of South Shields at a cost of £200, being funded from a gift of £600 by Mrs. T. Perry of Harton Village, South Shields, in memory of her late husband.

Miss Moore, daughter of the Mayor of South Shields, performed the naming ceremony at the Coble Landing. This was followed by a display of the Tom Perry’s abilities including a demonstration of her self-draining capacity, when boys from the training ship Wellesley filled the lifeboat with water.

TWCMS : B9761

***

Decorated whale’s eardrum, 1950s

This curious item is a decorated whale’s eardrum. Whalers would save the eardrums and paint them to look like a human face. This one was painted by William Bennett of South Shields, when he worked as a plumber on the whaling ships in the 1950s.

The whale factory ships Southern Harvester and Southern Venturer were regular visitors to Middle Docks in the 1950s and ‘60s. When the whalers were in dock, the smell of rancid whale oil pervaded the town, and Middle Docks workers were decidedly unwelcome on public transport! Yvonne Grunson’s grandfather Jim Stephenson worked on the whale factory ships at Middle Docks in the ‘50s; Yvonne recalls her mother saying that her dad would bring home whale oil, to be used to rub on the children’s legs when they were sore!

TWCMS : 2002.983

***

Case 3

Postcards, early 20th century

“Wish you were here”

Clockwise from top left:

R. & W. Hawthorn, Leslie & Co. Ltd., Hebburn

Mercantile Dry Dock Co. Ltd., Jarrow

Palmers Shipbuilding & Iron Co. Ltd., Jarrow

Note the proximity of the terraced shipyard workers’ houses in the foreground of the Hawthorn Leslie postcard. Shipyard workers often lived very close to the yards, and close-knit communities developed over generations.

Would you send a postcard of your workplace?

Loan: Sandra Quinn

***

Merchant Navy discharge booklet, 1941-1952

Many apprentice fitters (mechanical engineers) went to sea after serving their time. One such individual was Edward Duncan, who was apprenticed in fitting and turning at Middle Docks, South Shields, from 1936 to 1940.

Two days after completing his apprenticeship, Edward went to sea as 5th Engineer aboard the Empire Tarpon, joining the ship’s crew at South Shields on 30 December 1940. While with the SS Ocean Vista as a 2nd Engineer in 1943, Edward ferried troops and supplies during the invasion of Sicily and Southern Italy, and he would later recall that, “we were the first ship to enter Naples after the Nazis had been driven out, and came under continuous air attack whilst there”. Edward remained at sea until 1947, before having a spell on dry land, then returning to sea again from 1950-55.

TWCMS : 2022.186

***

The Hungry Thirties

Readheads, South Shields

The Great Depression of the 1930s sounded the death knell for many shipbuilding yards up and down the country, with very few new ships being built. Ship repair yards or shipbuilding yards with repair facilities were better able to weather the storm. At John Readhead & Sons Ltd. in South Shields, that yard’s ship repair facilities were a vital lifeline, as between 1931 and 1937 only one new ship was built at Readheads.

Jack Leighton served the first two years of his apprenticeship in Readheads’ marine engine dept., but he was forced to look elsewhere to finish the last three years of his apprenticeship when the Great Depression severely impacted Readheads and many of its workforce were let go. Jack was fortunate to get a position of apprentice tool fitter with Messrs. Prince-Smith & Sons Ltd. in Keighley, where he was able to finish serving his time. Jack was in Keighley when he received this letter in March 1931, from his friend R. Wake, whom he had known from Readheads.

The letter begins: “Many apologies for not answering your last letter, but with being out of work & sick of walking the streets one gets downhearted John & really you can’t bear to look at yourself in a looking glass”. The author continues, “Well John things are desperate up here. There is no one working at Readheads…” and he talks about his former work colleagues “all walking the streets & it will be months before we get a start again…”, adding “There is over 14,000 signing at the [labour] exchange now & still increasing”.

Referring to Jack’s move to Keighley, his friend says in the letter, “You did the best thing in your life as dear knows what these lads are going to do”. Jack’s move was indeed a smart one, as he would go on to become Managing Director and Chief Executive of Prince-Smith & Stells, the largest textile firm in Keighley. He was awarded an MBE for Services to Export in the New Year Honours 1979.

TWCMS : 2022.143

***

Token, early to mid 20th century

Palmers Dining Rooms

Palmers Shipbuilding & Iron Co. Ltd. built a hostel and canteen at High Lane Row, Hebburn – midway between the firm’s Jarrow and Hebburn Works – which opened in 1919. Latterly known as Simpson’s Hostel, it provided accommodation for 400 men, and the dining hall in the canteen could seat 800.

Never the twain shall meet…In the 1950s, Palmers Hebburn Co. Ltd. had several canteens on site at the Hebburn Works, frequented (separately) by manual workers, staff, managers and directors.

TWCMS : 2008.764

***

Cartoon, about 1977

Bob Fowler, the Stores Manager at Brigham & Cowan, is the subject of this cartoon by the Brighams Gate Man, Harry Bennet. It probably dates to July 1977, when the Queen and Prince Philip visited South Tyneside as part of their Silver Jubilee tour.

Poking fun at Bob’s transport arrangements – he was well known for cadging lifts from his workmates – Bob has outdone himself this time by managing to hitch a ride in the Royal limousine!

Donated by Marilyn Haines (née Fowler), the only child of Bob and Winnie Fowler.

TWCMS : 2022.94

***

Demarcation booklets, 1903 and 1928

A busy shipbuilding or ship repair yard was home to a multitude of trades, each specialising in different jobs and with different skills. Look out for the full list of trades elsewhere in this exhibition!

Demarcation required that specific jobs were assigned to particular trades. Some trades had skills that overlapped, meaning that in theory either trade was capable of doing the work. As shipyard workers were often paid by piecework, rather than a flat wage, they would vie for all the work they could get, and disputes would sometimes arise. To settle arguments over who should do what, rules were published in booklets such as these. The booklet from 1903 lists the demarcation of work on Tyneside between shipwrights and ship-joiners, while the one from 1928 specifies the work of Tyneside’s engineers and plumbers.

TWCMS : 2022.293

***

Postcard, about 1910

The iconic cableway cranes at Palmers feature prominently in this postcard from about 1910. The overhead electric trolley cranes with their distinctive elliptically-shaped gantries began to be installed in 1906 and were a prominent feature of Jarrow’s skyline. They were demolished following the collapse and sale of Palmers’ Jarrow yard in the 1930s.

TWCMS : 2016.422

***

Share certificates, 1868 and 1984

Shares are issued to investors to help companies raise funds.

Charles Mark Palmer founded Palmer Bros. & Co. with his elder brother George at Jarrow in 1851. In 1865 the firm became Palmers Shipbuilding & Iron Co. Ltd., and the works were expanded to include blast furnaces and an iron rolling mill. This share certificate was issued in 1868 to Sir William Hutt of Gibside, Co. Durham, who was the MP for Gateshead from 1841-1874.

In 1984 caulker/burner Eddie Pippin invested in shares when Readheads Drydocks was purchased from British Shipbuilders in a worker buyout, becoming Readheads Shiprepairers Ltd. The venture was short lived, as the following year the fledgling firm was sold to Tyne Dock Engineering Ltd. and the site renamed TDE West.

TWCMS : 2016.681, 2022.295

***

Contract, 1889

Palmers built many vessels for the Royal Navy as well as for the navies of other nations. When it came to naval work, Palmers reputation travelled far and wide. On one occasion, so the story goes, when naval matters were being discussed with the heads of the Admiralty of a “great European power”, an official proclaimed, in the accent of his mother tongue, “Oh, yes, we know Pal-mare”.

In 1889 Palmers agreed to supply the designs and specifications for three armoured cruisers to be built for the Spanish Government at Bilbao. The Infanta Maria Teresa, Vizcaya and Almirante Oquendo were built between 1889 and 1893. In 1898 all three were sunk in action against the United States Navy at the Battle of Santiago de Cuba during the Spanish-American War.

TWCMS : 2016.684

***

Football medal and badge, 1935 and 1946

Medal, South Shields Junior League Shield, awarded to ‘R.T.’ who played for Readheads Juniors, 1934-35. We think the recipient’s surname may have been Thwaite or Thewitt.

Badge, Jarrow & District J.O.C. Football League runners-up, awarded to William Stephenson who played for Readheads Juniors.

TWCMS : 2021.84, 2022.298

***

Plinth 3

Welder’s protective clothing and headscreen, 1970s

This collection of welder’s protective clothing came from John Readhead & Sons Ltd., South Shields, including a blue cotton boilersuit, leather apron, kneepads, flameproof hood and green leather welder’s mitts.

TWCMS : H18054.1, H18054.2, H18054.4, H18054.5, H18054.6, H18055.1

***

Case 4

Bombing targets, 1940

This aerial photograph is marked with targets for Luftwaffe bomber crews on raids to the Tyne, including Brigham & Cowan Ltd., Tyne Dock Engineering Co. Ltd., Middle Docks & Engineering Co. Ltd., and John Readhead & Sons Ltd.

TWCMS : 2008.323

***

Royal visit to Tyne shipyards, 7 April 1943

John Readhead & Sons Ltd.

King George VI and Queen Elizabeth received a “real hearty welcome” when they visited three North East shipyards in April 1943, including the Hebburn Shipbuilding Yard of R. & W. Hawthorn, Leslie & Co. Ltd., and John Readhead & Sons Ltd. at West Docks, South Shields.

John Herriott of 37 Tynedale Road, South Shields was one of the Readheads employees with long service who were presented to the Royal visitors. John was the Chief Cashier at West Docks and had worked there for 41 years.

Immediately after the Royal visit, an excited John dashed off this letter to his daughter Jean. He wrote: “The King & Queen visited Readheads today, and I was among the employees with long service, who had the great honour of being presented to their majesties, who each shook hands with me. They both were extremely gracious & conveyed the impression that they were personally interested in those presented. The King seemed to be somewhat weighed down by the cares of state, the Queen was really the most charming unaffected person I ever came into contact with, and created a great & good impression with everyone, by her charming smile and magnetic personality. Her photos do not do her anything like justice. In spite of the terrific wind, the worst we have had, she was quite unperturbed, and gave no sign of discomfort. The King was in naval uniform, the Queen was dressed in a two piece, lovely shade of amethyst, & carried a fox fur. Mammy came down to the office & had a grand view of the proceedings. She quite enjoyed the experience, tho she couldn’t see us presented. Well that’s all. Dad”.

TWCMS : 2022.69

***

Silver salver, 1941

This magnificent sterling silver salver was presented to Mrs Hélène Chapman when she launched HMS Pathfinder at Hawthorn Leslie’s Hebburn Shipbuilding Yard on 10 April 1941. During the war, Hélène was the South Shields Centre Leader for the Women’s Voluntary Service and her husband, Col. Robert Chapman, was County Welfare Officer for the Armed Services.

When R. & W. Hawthorn, Leslie & Co. Ltd. wrote to Hélène asking if she would launch the destroyer, they emphasised that although all arrangements were to remain strictly secret and that the ceremony would be a “very quiet and simple one”, the Admiralty was nonetheless anxious that all warships be “correctly named” even in wartime, and that its ships be “launched in the traditional manner”. And so, on the appointed day, Hélène Chapman gave the traditional salutation: “I name this ship Pathfinder. May God guide her, and guard and keep all who sail in her”.

The salver was made by the Newcastle silversmiths Reid & Sons Ltd. (est. 1778).

Loan: Peter S. Chapman

***

Readheads visitors book, 1943-1970

King George VI and Queen Elizabeth were the first to inscribe their names in this visitors book, on their tour of North East shipyards in April 1943.

Other famous names which appear later include J. Chuter Ede, MP for South Shields (several visits) and Prime Minister Harold Wilson (visited 6 June 1969).

Loan: Rodney Towers

***

Case 5

Miniature ship’s wheels, early to mid-20th century

Apprentice fitters would make miniature brass ships wheels as a way to practice their metal turning skills.

These examples were made by Jim Stephenson at White’s Oil Burning Co. (then based on Wapping Street, South Shields) and Bob Jordan at Middle Docks & Engineering Co., South Shields. Bob served his time at Middle Docks from 1951 to 1956, and was later the Yard Manager.

TWCMS : 2022.247.1

Loan: Yvonne Grunson

***

Lighters, Second World War (1939-1945)

Jewellery box, 1950s

These cigarette lighters were made at Palmers Hebburn Co. Ltd., using 1d and 1/2d coins. The jewellery box was made at Hawthorn Leslie’s yard in Hebburn.

TWCMS : 2016.858, 2016.859, TWAM: Recent acquisition

***

The Hungry Thirties

Palmers, Jarrow

70 per cent of Jarrow’s workforce were made unemployed when the mighty Palmers Shipbuilding & Iron Co. Ltd. collapsed in 1933. Palmers’ Jarrow yard was sold to National Shipbuilders Securities, which closed it down in order to sell it and shipbuilding in Jarrow was banned for 40 years.

Bob Fowler was one of the more than 7,000 workers to find themselves unemployed. This reference from the yard’s Receiver and Manager, Sir W.H. Peat, ends with the rather matter-of-fact statement, “His services were dispensed with owing to depression in trade”.

TWCMS : 2022.87

***

Token, late 19th to early 20th century

This token was issued by the Steel Works Department at Palmers Shipbuilding & Iron Co. Ltd., and is numbered ‘609’. It was found by metal detectorist Warrick Rochester in the surprising location of a field at Boldon. We’re uncertain about its original purpose – perhaps to do with the issuing of tools, or recording of timekeeping?

TWCMS : 2021.88

***

Badges, 1940s-1980s

The folk of South Shields are rightly proud of the part played by their forefathers in the development of the lifeboat, an invention which would go on to save innumerable lives worldwide. When the town’s coat of arms was designed in 1850 it featured a lifeboat, crewed by hardy Tyne pilots, at its centre. Here are some examples of local insignia which have also featured Shields-pattern lifeboats over the years.

Badge, South Shields Ex-Schoolboys’ FC, 1940s

Badge, South Shields Grammar-Technical School for Boys, 1960s

Badge, South Shields FC, 1980s

TWCMS : 2012.1285.4, 2019.253, 2019.365

***

Programme and print, 1976

The Dalkeith was converted from a bulk carrier to a drill ship by North East Coast Shiprepairers Ltd. at Middle Docks, South Shields in a complex 18 month operation. Middle Docks had experience of this kind of work, having converted the Wimpey Sealab from a paper pulp carrying vessel into a dynamically positioned drill ship four years earlier in 1972.

TWCMS : 2022.288.1, 2022.289

***

Tools of the Trade: Tracer

Used by Irene Hills who was apprenticed as a tracer at R. & W. Hawthorn, Leslie & Co. Ltd., Hebburn, 1947-1952. Irene’s tools include: powdered chalk, pens, ink compasses, ink sticks & ink mixing palette, stencils, eraser and erasing shield, tacks and paper weights.

Design draughtsmen would design ships using pencil and paper, then it was the job of tracers to make finished copies of those initial plans on special waxed cloth, using Indian ink, so that they could be reproduced for the various shipyard departments that would require them.

TWAM: Recent acquisitions

***

Case 5 – shelf

South Shields and the Invention of the Lifeboat

In March 1789 the collier brig Adventure was wrecked on the Herd Sands at the mouth of the Tyne. The ship’s crew drowned just 300 yards offshore, in plain sight of many onlookers who were powerless to intervene. What we now know as a “lifeboat” did not then exist.

The wreck of the Adventure prompted a group of local shipowners and prominent citizens, known as ‘The Gentlemen of the Lawe’, to place an advert in the Newcastle Courant, offering a reward of two guineas for a plan of a boat which would “preserve the lives of seamen, from ships coming ashore, in hard gales of wind”.

Local men Henry Greathead and William Wouldhave both made submissions. Both men’s designs were deemed unsuitable for the local conditions prevalent at the mouth of the Tyne, so The Gentlemen of the Lawe determined to produce a design of their own. Wouldhave was offered one guinea for his trouble and Greathead, being a South Shields boatbuilder, was tasked with the construction of a boat to the Gentlemen’s design principles: to be buoyant with a shallow draught, to have elevated ends, and for each end to be alike.

In the opening years of the nineteenth century Greathead sought official recognition as the “inventor of the lifeboat” and he in fact managed to persuade Parliament, Trinity House, and Lloyds of London of his claim, receiving substantial financial rewards. Wouldhave was incensed, claiming that important elements of his own design had been incorporated into that first lifeboat, on the back of which Henry Greathead was now profiting. Nicholas Fairles, who had chaired the committee established by The Gentlemen of the Lawe in 1789, also refused to acknowledge Greathead as the inventor, although he conceded that the committee had adopted Greathead’s suggestion that the boat have a rockered or curved keel to aid manoeuvrability.

Both Wouldhave and Greathead would take the claim of being the inventor of the lifeboat to their graves. In the last years of his life Greathead was imprisoned for debt and twice declared bankrupt, dying age 63 in 1818. Wouldhave died poor and neglected, age 73 in 1821.

A memorial commemorating both men, but universally known as the “Wouldhave Memorial”, was erected on Pier Parade in 1890, and the popular Tyneside painter Ralph Hedley painted a portrait of Willie Wouldhave in 1896. Look out for Hedley’s painting, as well as the original model Wouldhave submitted to The Gentlemen of the Lawe, on display in the museum’s ‘Changing Faces’ gallery downstairs.

TWCMS : G6018, K4551, 2011.1899, 2021.130

***

Postcard, early 20th century

The Palmer Memorial Hospital was built at Jarrow by Charles Mark Palmer in 1870, in memory of his first wife Jane who had passed away in 1865. The Hospital was maintained by the contributions of Palmer’s workmen, supplemented by an annual subscription from the company, for the exclusive use of the firm’s employees and their family members. Before its construction, men and boys in the shipyard or iron and steel works had to be taken by horse and cart to the Newcastle Infirmary; some did not survive the journey.

TWCMS : 2016.418

***

Tankard, 1965

Every Readheads employee was given a pewter tankard to celebrate the firm’s centenary in 1965. This one was owned by Margaret Rose, who worked at Readheads from 1954 to 1966. Margaret started out as a shorthand typist, eventually becoming the private secretary to G.H.R. Towers, Readheads Chairman and Managing Director.

TWCMS : 2011.353

***

Photograph, 1995

Lights! Camera! Action! In July 1995 No. 4 Dock at Middle Docks (by then renamed TDE Hill Street) was used to film a scene for the Festival Film & TV mini-series The Tide of Life, based on one of Catherine Cookson’s novels. In this image TDE employee Peter Burnett is kitted out in period costume as an extra.

TWCMS : 2022.244

***

Shields pattern lifeboat model, early 19th century Baudsey Woodbridge

South Shields boatbuilder Henry Greathead built his first “life-boat”, retrospectively christened the Original, in 1789. Although Greathead’s later claim, to have been the sole “inventor” of the lifeboat was disputed, there can be no denying that in 1789 South Shields gave birth to a purpose-built lifesaving boat which was the first to achieve general acceptance and practical success.

This model is of an early Shields pattern lifeboat built by Greathead in South Shields in 1801. It was the seventh lifeboat to come out of Greathead’s boatyard, and was made for Bawdsey Haven in Suffolk, where it was stationed until transferring to nearby Woodbridge Haven in 1825. Although slightly bigger than the Original, Baudsey Woodbridge is essentially of the same design.

The characteristics of a Greathead-built ‘Life Boat’ were: double-ended hull form (i.e. stem and stern alike); well-rockered (curved) keel for manoeuvrability; flat-sectioned bottom amidships; heavy, strengthening ‘bilge-trees’, similar to a coble’s ‘drafts’; the sharp, coble-like, turn to the bilge (between bottom and sides); raking stems in the form of an arc; hollow waterline entrances, for ease of rowing, and ‘flaunching’ (flared) bow sections to deflect the sea above; external cork belting for fendering and buoyancy; clinker planking on heavy frames and doors; cork buoyancy below the side benches; five rowing thwarts with six sets of tholepins (so that by the oarsmen turning round the boat could be rowed in either direction); central ‘gangboard’ (missing on this model) for ease of the crew’s and survivor’s movement; raised end platforms for steersmen; prominent, paired timber-heads for use when fastening alongside wrecked vessels; short rowing oars, long steering oars and ‘puoy’ (pushing off pole).

TWCMS : B9746, 2007.5835

***

Medals, First World War (1914-1919)

Watch fob, about 1920 Medals awarded to Chief Petty Officer Charles Callender of the Royal Naval Volunteer Reserve. Callender served his apprenticeship with Readheads and was a journeyman plater at the South Shields shipyard at the time of his enlistment. He won the Distinguished Conduct Medal for his actions in France on 5 February 1917, when he kept the enemy at bay, holding a difficult position for ten hours until relieved.

The enamelled gold watch fob was presented by the officials and workmen of Readheads’ shipbuilding and engineering works, to Harold E. Beverley, as a “token of gratitude” for his service in the First World War. 371 were issued to those who had returned from the war, and a further 137 were distributed to the families of men who had died on active service.

TWCMS : J6902, 2017.2270

***

Case 6

Anchor model, mid 20th century

This is a model of the Taylor Stowable Anchor which was designed and patented by John Taylor, Foreman Loftsman at the Hebburn Shipbuilding Yard of R. & W. Hawthorn, Leslie & Co. Ltd.

Through his work in the mould loft, John would have been well aware of the problems of stowing anchors close to the side shell of a ship, which curves in all directions in way of the anchor hawse pipes. John Taylor designed this stockless anchor with its crown in two parts, each part adjusting independently to allow the flukes to stow closely to the shape of the ship’s shell when the anchor is raised. This successful anchor design was approved for use on all ships classed “100 A1” by Lloyds.

Honouring his work at Hawthorn Leslies in the Second World War, John Taylor was awarded the British Empire Medal.

Loan: Jarrow & Hebburn Local History Society

***

Tools of the Trade: Caulker/burner

Donated by Peter Longstaff who worked at Tyne Dock Engineering Co. Ltd., South Shields, from 1972. This pneumatic caulking hammer was used at TDE and may date to about the 1950s. Peter said:

“In the Seventies when the ship came into the dry dock for shell repairs, the carpenters would rig the staging up. The ancillary workers would scale the damaged shell. After the plater marked it off, he would scale off the old paintwork. Then the burner would burn the damaged shell plate out. The caulker would be sent to clean up the shell plate which the burner cut out with his burner. The caulker would chamfer the plate to leave a nice finish for the plater to mark off his new shell plate. He would then fit his new plate, dogging it up, then the welder would weld up the new shell plate. After that the caulker would go back to the shell plate to clean up. Then the painter would go on to paint the new work with so many coats of paint. Then, with the painting done, the new shell plate gets tested and passed by the supervisor, then the staging is taken down ready for another job.”

TWCMS : 2011.3169

***

False arm attachments, early 20th century

William Humphreys lost his right arm while serving in the Royal Navy in the First World War. Following the war, he was fitted with a false arm which enabled him to continue working. For 15 years he worked in the Tool Stores and the Admiralty Buildings at Palmers in Hebburn, becoming Superintendent of the Royal Naval Stores. Mr Humphreys gave up his job to someone else in 1936 in order to join the Jarrow March to London. When he died in 1973, the main section of his false arm was cremated with him.

TWCMS : 2001.3546

***

Pass and ID card, 1970s-1980s

Pass for Swan Hunter’s “South Shields Shipyard” (formerly Readheads) issued to welder Alan Thompson.

ID card issued by Tyne Dock Engineering Ltd., South Shields, to plumber Norman Wales.

TWCMS : 1995.2788, 2022.283

***

Card and booklet, 1960s and 1990

When John Bage joined John Readhead & Sons Ltd. as an apprentice draughtsman in 1964, the South Shields yard issued him with this pocket-sized card of “Instructions to new starters for their general safety and welfare” listing 26 Dos and Don’ts. Although there was an increased awareness of health and safety in the 1960s, old habits die hard and the pace of change was slow.

Fast forward to November 1990 and the 94-page health and safety manual issued by Tyne Dock Engineering Ltd., by which time an awareness of and legislation governing health and safety had come on leaps and bounds.

TWCMS : 1995.2847.1

Loan: John Bage

***

Tools of the Trade: Rigger

Used by John Forrest who went to sea age 15 ½ where he learned the art of rigging. John’s tools include: rigger’s spikes and knife, sharpening stone, Swedish fids, palms, hard eyes, eyelet punch, beeswax. These tools were used by John in all the yards on the Tyne, the first being at the Mercantile Dry Dock Co. Ltd., Jarrow.

TWAM: Recent acquisitions

***

Case 6 – shelf

Freedom of South Shields, 1967

The Freedom of the County Borough of South Shields was bestowed on George Harold Readhead Towers “in recognition of the eminent services rendered by him to the Borough”. G.H.R. Towers was the last Chairman and Managing Director of John Readhead & Sons Ltd., the family firm of shipbuilders, ship repairers and marine engineers which brought so much employment and prosperity to South Shields for over a century.

Loan: Rodney Towers

***

Press release and leaflet, 1966-1967, Sea Freightliner I&Sea Freightliner II

Readheads built Britain’s first cellular container ships, Sea Freightliner I and Sea Freightliner II in 1968 for the service between Harwich and Zeebrugge, designed to carry 218 20-ft containers. Modern container ships are now vastly bigger and can carry anywhere between 10,000 and 21,000 containers!

This press release was originally owned by Tony Chambers, who was the Maintenance Manager in charge of plant and equipment maintenance at John Readhead & Sons Ltd. Tony’s son, Philip, recalls the occasion when his dad showed him this very document at the kitchen table one morning. “It is his pride” says Philip, “that is uppermost in my memory when I recall the moment we sat together and pored over the pages of a document which described and illustrated the two cellular container ships to be built at Readheads”. The fact that they were to be the first of the type to be built in Britain, revolutionising the way in which cargo would be stored, had Philip’s “usually rather taciturn dad waxing lyrical”.

Look out for the half model of Sea Freightliner I and II, also on show in this exhibition.

TWCMS : 2017.2284, 2022.39

***

Ticket, 1974

The legendary Hebburn-born Arsenal FC winger George Armstrong started out playing for Leslies Juniors, the works team of Hawthorn Leslie (Shipbuilders) Ltd. Other Leslies’ players to have trials at Arsenal were George Armstrong, Ricky Bainbridge, Brian Bettis, David Frampton, Gordon Lamb, Ronnie Tatum and Colin Veitch.

George Armstrong made a record 621 appearances for the Gunners between 1962 and 1977. Voted Arsenal’s Player of the Year in 1970, the following season he played in every match, and it is estimated that George had a hand in more than half of the goals scored in that memorable League and FA Cup double-winning season.

Loan: Joe Armstrong

***

Model and photographs, 1978-1979

In the late 1970s, for the first time ever in a British shipyard, a ship was successfully cut in two horizontally. The ship was the Swedish roll-on/roll-off ferry Stena Oceanica and the yard that tackled this technically difficult job was Tyne Shiprepair Group’s Middle Docks yard in South Shields.

Stena Oceanica was cut horizontally so that four decks of passenger accommodation – weighing 2,500 tons – could be lifted by hydraulic jacks and a new centre section fitted, increasing the height of the vessel by 1.5 metres. All the internal services and controls such as main engine exhaust uptakes, boiler uptakes, fresh and salt water service pipes, navigation controls, fire detecting and extinguishing services, electric cables and two passenger lifts were extended and recoupled into existing services.

The lifting operation began at 08:30 on Monday 27 November 1978. Middle Docks Head Foreman Shipwright Tommy Houlsby (pictured here, beside one of the jacks) was in overall control, signalling the commencement of jacking with three blasts of his whistle. Two days later it happened to be Tommy’s birthday, so on that morning when Tommy blew his whistle, instead of jacking, the men all sang a loud and raucous version of Happy Birthday!

The steel and brass model of the hydraulic jacks used aboard Stena Oceanica was owned by Middle Docks yard manager Bob Jordan, who had a hand in their design.

TWCMS : 2022.228, 2022.253

Loan: Lynn Houlsby

***

Case 7

Apprenticeship indentures and certificates

Shipbuilders and ship repairers took on apprentices who would “serve their time” learning a trade. The duration of apprenticeships varied over time, but a period of five years was common. Apprentices would be started out on simple tasks, gradually working up to more complex jobs as they gained skills and confidence.

The school leaving age was 15 (or 14 prior to 1947) but you had to be 16 to start an apprenticeship, so many would-be apprentices worked in the general store or the time office until they were old enough to begin to serve their time. Apprentices learned from experienced tradesmen known as “journeymen”.

The “Indenture of Apprenticeship” was a binding contract between the apprentice, his or her parent or guardian, and the shipyard. In William Frame’s contract with the iron ship and boiler builder Joseph T. Eltringham in 1888, young William promised that he wouldn’t “contract Matrimony within the said Term nor play at Cards or Dice Tables or any other unlawful Games”. It was also stipulated that “He shall not haunt Taverns or Playhouses”.

John Readhead & Co., South Shields, Charles Wrigglesworth, apprentice ironship riveter, 1883-1885

Joseph T. Eltringham, South Shields, William Frame, apprentice boiler riveter, 1888-1892

R. & W. Hawthorn, Leslie & Co. Ltd., Hebburn, John Donald Westoby, apprentice fitter, 1918-1923

R. & W. Hawthorn, Leslie & Co. Ltd., Hebburn, Irene Whitworth (later Mrs Irene Hills), apprenticetracer, 1947-1952

John Readhead & Sons Ltd., South Shields, Alan Thompson, apprentice welder, 1955-1960

Swan Hunter Shipbuilders Ltd., Hebburn Dock, Robin Tennet, apprentice painter, 1974-1978

TWCMS : 2011.298, 2016.696, 2017.936, 2022.282

Loans: Irene Hills, Robin Tennet

***

Photograph, 1920

Hebburn Shipbuilding Yard Ambulance Corps

The gentleman at centre back is Newman Battman, a commissionaire and ambulance man at R. & W. Hawthorn, Leslie & Co. Ltd. Before coming to work at Hawthorn Leslie’s, Newman had been a Bombardier in the British Army. His son Gordon also worked at Hebburn Shipbuilding Yard, as a blacksmith.

Newman’s great granddaughter Lynda remembers her mother Doris, daughter of Gordon and Elizabeth Battman, talking about the children who would hang around Hawthorn Leslie’s gate shouting “Any bait left?”. Doris was told off by her mother for doing this, lest folk should think that the Battmans were struggling to make ends meet!

TWCMS : 2022.297

***

Document, 1991

Bill Edwards was apprenticed as a plater at John Readhead & Sons Ltd., South Shields, eventually becoming Head Foreman Plater at the West Docks yard. Like many of his contemporaries, Bill’s health suffered as a result of the job he did, the tools used and the dangerous substances he was exposed to.

In 1991 Bill was assessed as suffering from Vibration White Finger, caused by prolonged use of vibrating tools, the effects being “Pain, numbness and tingling of fingers, worse in cold weather. Difficulty in handling objects”. But his claim for disablement benefit under the Industrial Injuries provisions was denied because “disablement has been assessed at less than 14%” and because he had not made a claim before 1986, despite having worked in the industry since 1950. Bill was from a generation which accepted unpleasant and often dangerous working conditions as par for the course, and when in later life he realised the consequences of what he’d been exposed to, it was too late.

In 1999 Bill was found to have a lung tumour, and following his death in 2001 the coroner’s verdict was that exposure to asbestos in the shipyard was the most likely cause of his death.

TWCMS : 2022.30.1

***

Football trophies, mid to late 1950s

South Tyne Junior Football Association Cup Winners 1954-55, Leslies Juniors

Jarrow & District J.O.C. Football League Div. 1 Champions 1954-55, Leslies Juniors

North East Industrial Welfare Football League Cup, Joint Holders 1958-59, Leslies Apprentices

Trophies won by Ronnie Mogie (born Jarrow, 1939) who served his time as a fitter at Hawthorn Leslies in Hebburn. Ronnie played for Leslies Juniors and Leslies Apprentices, as well as the Durham County Army Cadet Force football team.

TWCMS : 2019.231, 2019.232, 2019.234

***

Union cards

Amalgamated Society of Woodworkers (Edwin Scott, Joiner, apprenticed at Middle Docks & Engineering Co. Ltd.)

50 years membership card, Amalgamated Society of Woodworkers (John D. Clasper, Joiner, retired from John Readhead & Sons Ltd., 1957)

Amalgamated Engineering Union (Donald Curry, Coppersmith, apprenticed at Middle Docks & Engineering Co. Ltd.)

United Society of Boilermakers and Iron & Steel Shipbuilders of Great Britain and Ireland (Bill Edwards, Plater, apprenticed at John Readhead & Sons Ltd.)

Amalgamated Society of Boilermakers, Shipwrights, Blacksmiths and Structural Workers (David Todd, Iron Caulker, apprenticed at John Readhead & Sons Ltd.)

Apprentice’s card, United Society of Boilermakers, Shipbuilders and Structural Workers (Alan Thompson, Welder, apprenticed at John Readhead & Sons Ltd.)

United Society of Boilermakers, Shipbuilders and Structural Workers (James Stewart, Welder, apprenticed at Palmers Hebburn Co. Ltd.)

General, Municipal, Boilermakers and Allied Trades Union – Boilermakers’ Section (Ron Dunn, Shipwright, apprenticed at Readheads Dock, South Shields)

TWCMS : 2008.1508, 2021.96, 2022.27, 2022.86, 2022.162

Loan: Edwin Scott

***

Plinth

TDE overalls, 1990s

These overalls were issued to plater Billy Bell, who served his time at Brigham & Cowan Ltd., South Shields, from 1949. Billy remained with Brigham & Cowan until 1962, before going to work at Tyne Dock Engineering Co. Ltd., where he mainly worked for the rest of his career.

TWCMS : 2021.125

***

Case 8

Home Guard photograph, 1942

Officers and NCOs of “F” Company 8th Durham (South Shields) Battalion Home Guard pictured at Marsden Hall in 1942. “F” Company was based at and composed of employees of Middle Docks & Engineering Co. Ltd., South Shields.

“F” Company was established soon after Secretary of State for War Anthony Eden’s call for ‘Local Defence Volunteers’ on 14 May 1940. Its members served to protect Middle Docks, and the important service it was providing to the war effort, until the threat of invasion receded and the Home Guard was officially stood down on 3 December 1944. On 15 December 1944 “F” Company held a special “Stand-Down Dinner” in the Unity Hall, Mill Dam, South Shields.

Back row L to R: Sgt. Wardle, Sgt. Tose, Sgt. G. Pilkington, Sgt. R. Galbraith, Cpl. Catchpole, LCpl. H. Clavery.

Middle row L to R: Cpl. S. Spencer, Sgt. E. Hardy, LCpl. J. Allen, Sgt. Watson, Sgt. G. Harris, Sgt. Maj. E. Standing, Cpl. J. Brown, LCpl. G.A. Steele, LCpl. C. Campbell, Cpl. J. Allen

Front row L to R: 2Lt. G. Heron, 2Lt. H.E. Ratter, Lt. T. Goudie, Maj. J.W. Hair, Cpt. G. Gray, Lt. J. Ward, 2Lt. H. Snowling

TWCMS : 2008.1528

***

Badges, First and Second World Wars

In times of war, shipbuilding and ship repair were vitally important to the war effort, and workers were exempted from military service. Badges were issued to workers in these industries to show that they were ‘doing their bit’ for their country.

The War Service badge issued by John Readhead & Sons Ltd., South Shields, was worn by Anthony Carr. Anthony served his time as a riveter, but later retrained as a welder when riveting was on the decline.

The Palmers badge was issued to fitter Harry Tallack, who worked at Palmers Hebburn Co. Ltd. during the war.

TWCMS : 2016.856, 2016.1344, 2016.1345

Loan: Eleanor Mulley

***

Home Guard records, 1940-1944

Initially known as the Local Defence Volunteers, the Home Guard was established in May 1940. It was made up of volunteers aged between 17 and 65 who were not eligible for military service because they were either too young or too old, or employed in ‘reserved’ occupations vital to the war effort. The role of the Home Guard was to act as a secondary defence force in case of invasion by Nazi Germany.

Most Home Guard units were workplace-based. This ledger records the activities of “F” Company 8th Durham (South Shields) Battalion Home Guard, which was based at Middle Docks & Engineering Co. Ltd., South Shields, and whose members were employed by that firm.

“F” Company’s main duty was to protect the property of the Middle Docks – which was undertaking vital war work by repairing both Royal Navy and Merchant Navy vessels –ensuring that only authorised persons were permitted entry,guarding the premises in the hours of darkness, and being ever-vigilant to the threat of fifth column saboteurs.

Members of “F” Company were trained in firearm use at the Londonderry Hall on Imeary Street, at Bolingbroke Street Drill Hall, and at Whitburn Rifle Range, and also practiced throwing live grenades at Trow Rocks on Saturday afternoons.

On the morning of Sunday 25 May 1941 “F” Company took part in an exercise in which the whole of the defences of South Shields were manned in “battle order” and possible incidents were rehearsed, including street fighting practice with imagined snipers in houses and motorcyclist troopers attempting to break through street barriers.

TWCMS : N2488

***

Spokeshave, 20th century

A spokeshave is used to shape and smooth wood. This one was used by David Duncan at Readheads shipyard, South Shields. David served his time at Readheads as a drafting loftsman, beginning in 1960. He had wanted to be a shipwright, but his diminutive height and frame precluded his entry into that trade. As a drafting loftsman, David would use the draughtsman’s plans to draw the ships’ plates out full-size on the mould loft floor and make wooden templates.

TWCMS : 2021.107

***

Letter and bomb tail fin, 1941

Readheads was badly affected by bomb damage on 9/10 April 1941. This letter was sent to Frank Carr, a plater’s helper at Readheads, thanking him for working hard to extinguish fires and incendiaries “in spite of continuous danger from High Explosive Bombs”.

That night the joiners’ shop and sawmills were completely gutted, the quay was rendered unusable, and the dock fitting shop, blacksmiths’ shop, engine works and boiler shop were all badly affected.

Displayed alongside the letter is the tail fin of an incendiary bomb which was dropped on Stanley Street, Jarrow, on 10 April 1941. Incendiary bombs were designed to cause damage by starting fires.

TWCMS : 2016.850

Loan: Walter Carr

***

Case 9

Palmers Ambulance Corps

Photograph (1912) and competition shield (1916)

Shipbuilding and ship repair were dangerous industries, and accidents happened all too frequently. Ambulance corps were established in yards to provide first aid to the injured. Shipyard ambulance corps were often closely associated with the local St. John Ambulance Brigade, and in June 1916 the 24 members of the then Palmers Ambulance Corps formed the nucleus of the Jarrow Ambulance Division of the St. John Ambulance Brigade.

This impressive shield was first competed for on 22 August 1916 by teams of Ambulance Corps men at Palmers in Jarrow. Five teams of men took part in the mould loft, having been set five tests by Drs. O’Neill and McPherson. One of the tests was: “A compound fracture to the right thigh and a fractured skull, the accident supposed to happen in a place where there is only a scuttle exit”. After the competition, there was a demonstration of “several methods of life saving” at Jarrow Baths, “ably demonstrated by Mr. H. Hunting (captain to the corps) and Mr. S. Pollock (secretary to the corps)”. Both gentlemen “entered the water fully dressed”.

TWCMS : 2016.236, 2022.291

***

Rule book and Leek Club trophy, 1962 and 1988

Brigham & Cowan Employees’ Welfare Club Ltd.

The popular Brighams social club has long outlived the ship repair yard itself, which closed 40 years ago this year. In 1962 annual membership of the Club was 2s 6d, or 1s for lady members.

Loan: Brigham & Cowan Employees’ Welfare Club Ltd.

***

Photograph, 1936-38

In this photograph the men of the Ambulance Corps at Palmers Hebburn Co. Ltd. are pictured with a regular ambulance stretcher and a boxed Singleton’s Ambulance Chair.

The Singleton’s Ambulance Chair was the invention of brothers John Foster Singleton and Thomas Hogg Singleton, both boilermakers at Palmers Shipbuilding & Iron Co. Ltd., Jarrow. The Singleton brothers’ Ambulance chair was designed to raise or lower an injured person from spaces such as ships’ holds, coal bunkers, engine rooms and other places not suited to the use of ordinary ambulance stretchers. The Chair was made of sail cloths stiffened with leather, with brass eyelet holes at the front and back, and leather straps and buckles at the sides. Using iron clip hooks and ropes the Chair, with patient, could be raised or lowered by just two persons hand over hand, or by means of a block and tackle. The patient was prevented from coming into contact with any obstacles or projections by a person holding a guide rope attached to the Chair.

TWCMS : 2016.244

***

Membership card wallet, 1960s

Photograph, about 1960, Badge, 1960s

Sporting and social activities at John Readhead & Sons Ltd. were described in the firm’s centenary publication in 1965:

“Association and Rugby Football, Bowls and Tennis are played together with Inter-departmental Competitions. Annual events that also form an integral part of a composite Company include dinners, socials, dances and outings”.

The photograph displayed here is of Readheads’ rugby team, its members pictured in about 1960. They are, back row, L to R: Groundsman, Jimmy Armstrong, Joe James, Unknown (U/Kn), Ian Croft, U/Kn, John Ford, Roly McCourt, Ronnie Carrick, Tony Thursfield, Norman Tennent. Middle row, L to R: Bob Henzel, Lance Price, Dick Elliot, Albert Chisholm (Manager), Fred Short, U/Kn, U/Kn. Front row, L to R: Brian Cook, Mel Mullen. Can you help us with any of the missing names?

Opened in December 1961, the Readhead Social Club was at Ashley House on Stanhope Road. It had “all the requirements of a modern Club with a licensed bar and lounge, T.V. and billiard rooms” and was “run and maintained by joint contributions from the Company and employees”. Today it is the Ashley Pub. This membership card wallet was originally owned by Bill Edwards, Head Foreman Plater at Readheads. It is missing the membership card – maybe you have one that could be donated to the museum?

TWCMS : 2019.306, 2022.29

Loan: Brian Cook

***

Dominoes, early 20th century, Playing cards, mid 20th century

Many shipyard workers played dominoes, three card brag, or kicked a football about in their dinner hour.

This set of brass dominoes was made at Palmer’s yard in Jarrow by blacksmith David William Wilson (1900-1977). David suffered a serious injury to his right hand, while at work in the shipyard, and it was thought that the hand would need to be amputated. But thanks to the Ward Sister at Palmers Memorial Hospital in Jarrow, who asked for 24 hours to treat the injured hand with a poultice, in the end only two fingers were lost. Crucially David retained his thumb and the next two fingers, enabling him to keep working and support his family.

TWCMS : N641, 2022.152

***

Case 10

Bookplate, postcard, medal, beaker

When Jarrow was incorporated as a Borough in 1875, Charles Mark Palmer was the town’s first Mayor. Jarrow’s development and prosperity was largely down to Palmer and his mighty shipbuilding and iron works, so it should not seem surprising that the design for Jarrow’s original coat of arms referenced this, with the inclusion of a blast furnace at bottom left, and a steam barque at bottom right. The crest – a dragon holding a crescent – was also taken from Palmer’s own personal coat of arms, an example of which can be seen on the bookplate pasted to the nonpareil pattern marbled endpaper.

TWCMS : 2011.1909, 2016.682, 2016.860, 2022.292

***

Scrapbook, 1946-1964, T.R. Dowson & Co. Ltd.

Thomas R. Dowson established his ship repair firm at Tyne Dock in the last years of the nineteenth century. In 1902 Dowsons became a limited company, and when the firm celebrated its golden jubilee in 1952, it employed 300 men. Among the yard’s first customers in its early years were the London gas companies sending their colliers for repair, and in the 1950s the South Eastern Gas Board’s colliers were also regularly being overhauled at Dowsons. The firm also gained a reputation for the repair and refitting of small naval vessels in the Second World War, particularly corvettes, of which 24 were refitted at Dowsons. After the war, the yard remained busy under the Admiralty policy of keeping ships of the Reserve Fleet in a good state of maintenance.

This scrapbook was kept by the Managing Director of Dowsons, Mr. George Young. George began his career in ship repair in 1929, when he joined Middle Docks & Engineering Co. Ltd. as a junior. Six years later he became a member of Dowsons staff, and in 1949 he was made General Manager, becoming the firm’s Managing Director in 1959.

Loan: David Westring

***

Medal, 1920

Royal Antediluvian Order of Buffaloes, Sir Charles Mark Palmer Lodge, No. 942.

TWCMS : 2008.3485

***

Leaflet and trowel, late 19th century

This leaflet advertises H.S. Edwards & Sons (est. 1810) – graving dock owners, iron ship repairers, engineers and boiler repairers at High Docks, South Shields.

From 1821 up to 1899, the High Docks were operated by the Edwards family. Harry S. Edwards was joined in partnership by his two eldest sons, James and George, in 1875, dating this leaflet to the last quarter of the nineteenth century. In 1899 H.S. Edwards & Sons (of South Shields) and Edwards Brothers (of North Shields) were amalgamated with Smith’s Dock Co. under the new name of Smith’s Dock Co. Ltd. Then in 1924 the High Docks passed into the tenancy of John Readhead & Sons Ltd., and into their ownership in 1938, with the three original dry docks being infilled, and the construction of two larger docks and a new fabrication shop.

The silver trowel was presented to Nicholas Owen Esq. of Tyne Dock, when he laid one of the foundation stones of the new Primitive Methodist Chapel, at the corner of New Street and Laygate Lane, South Shields, in 1881. The new P.M. Chapel and schools were to “replace those at Corstorphine Town, which have recently been purchased for the extension of their premises by Messrs H.S. Edwards & Sons, of the High Docks”.

TWCMS : 2021.91, 2021.128

***

Booklet, ships docked at Middle Docks, 1935-1941

This pocketbook contains a meticulous record of all ships docked at Middle Docks & Engineering Co. Ltd., South Shields, including in the first couple of years of the Second World War. It is one of two such books kept by Dennis Carr, a Middle Docks labourer who assisted the Docking Master, Tommy Houlsby, by doing much of the prep work for dockings and undockings. The page shown is ships docked between 25 January and 1 March 1940.

Dennis had worked at Middle Docks since his teens, and had been promised an apprenticeship as a boilermaker, but the offer was rescinded just a few months after young Dennis had started in the yard, when a family member of one of the foremen was instead offered the prized apprenticeship.

In about 1957/58 Dennis, his wife Marion, his son Dennis jnr. and daughter Kathleen moved into accommodation right at the head of the big No. 4 Dock; upstairs was a house (formerly lived in by a Foreman Labourer by the name of ‘Street’) and downstairs was the dock labourers’ canteen.

Dennis jnr. remembers living in that house and being the only family to actually live within the dock compound. “It was a very strange experience” he recalls, a very noisy environment, and the nearby compressor house kept you awake at first, that is, until you became used to it, then it eventually got to be that you couldn’t get to sleep without the noise! Dennis jnr. served his time as a plumber at Middle Docks, and he recalls his foreman Stan Houlsby’s incredulity, the one time he was late for work. “How can you LIVE here, and still be late?” Stan barked!

Loan: Dennis Carr

***

Sovereign case and collection box, Pilot Cutter Protector tragedy, 1916

On the morning of New Year’s Eve 1916 the Pilot Cutter Protector (built in 1907 by J.P. Rennoldson & Sons, South Shields) hit a mine at the mouth of the Tyne. The vessel disappeared within a great cloud of smoke and sank instantly, with the loss of all on board, plunging the towns of South Shields and Tynemouth into grief.

This gold sovereign case belonged to 70 year old Tyne Pilot Robert Phillips (born in South Shields, 31 January 1846) who was the eldest of the 19 men and boys who died on board the Protector that morning. It is engraved with the monogram ‘RP’ on the front and is inscribed inside “From Elsie to Father”.

After the tragedy, the surviving pilots, who had not been aboard the Protector on that fateful morning, took it in turns to patrol the beaches, searching for bodies of the deceased. Robert Phillips’ body was the only one to be recovered, after more than two months. The body was found by Robert’s very own son Ralph, at Tynemouth on 5 March 1917, and the sovereign case was discovered on Robert’s person that sad day. It was passed down through the Phillips family and was latterly owned by Robert’s grandson, also named Robert Phillips.

The collection box was used to collect money for the families of those who perished. It was originally owned by Tyne pilot Alexander Wallace Harrison, and it is possible it was made from timbers recovered from the site of the tragedy.

TWCMS : 2013.1151, 2019.286

***

Photograph and coronation medals,

Alderman Robert Readhead Robert Readhead, eldest son of Readheads shipyard founder John Readhead, was Mayor of South Shields a record four times, serving two double terms in 1893-95 and 1910-12.

In June 1911, as Mayor and Mayoress of South Shields, Alderman and Mrs. Robert Readhead presented these medals to commemorate the coronation of King George V and Queen Mary.

Back at the shipyard, Robert Readhead was for many years in charge of the firm’s Engine Works, until his retirement in 1912.

TWCMS : F11738, G270, 2001.5001, 2007.2522

***

Case 11, Bottle and pump clip, 2009

Publicans and real ale enthusiasts Jess and Alison McConnell launched the Jarrow Brewery in 2002. The names of all the Brewery’s ales were inspired by Tyneside’s history and way of life. ‘Rivet Catcher’, an award winning champion ale, recalled the region’s shipbuilding prowess, and ‘Palmer’s Resolution’ was named after Sir Charles Mark Palmer, founder of Palmers Shipbuilding & Iron Co. Ltd.

TWCMS : 2009.2395, 2009.2408

***

Case 12

Engine nameplate, 1903

Engine builder’s plate from the tug Irlam, built and engined in 1903 by J.P. Rennoldson and Sons of South Shields. The Irlam, a steel paddle-tug of 100′ (30.5 metres) length, was built for service on the Manchester Ship Canal. South Shields yards such as Eltringhams and Rennoldsons had a worldwide reputation as tug builders.

TWCMS : H10548

***

Model, post-1960

This model of Jarrow’s Mercantile Dry Dock includes no. 4 dock, at far left, which was completed in 1960, dating the model to sometime after that date.

The Mercantile Dry Dock was established in the 1880s. In its latter years, the Mercantile was operated as part of the Court Line Group (as owners of North East Coast Shiprepairers Ltd.) and Tyne Shiprepair Group (part of British Shipbuilders Shiprepair Division) before the yard closed in 1981. The location of the former yard is today home to the Cemex Jarrow Aggregates Wharf.

TWCMS : 2021.142

***

Model of PS Eppleton Hall, Made by Gordon Taylor (1932-2019)

This model tugboat was made by Gordon Taylor of South Shields. Gordon served his time as a shipwright in the 1950s, working for T.R. Dowson & Co. Ltd. of Tyne Dock and Robsons Boat Builders Ltd. of Templetown.

In his retirement, Gordon lovingly constructed seven tugboat models from scratch, inspired perhaps by his father James, who had himself worked on River Tyne tugs. Each model took Gordon between nine months and a year to make.

This model is of the paddle steamer Eppleton Hall, which was built in 1914 by Hepple & Co. Ltd. of South Shields, for the Lambton & Hetton Collieries Ltd. In 1945 France, Fenwick Tyne & Wear Co. Ltd. were the next owners, then in 1964 ownership was transferred to the Seaham Harbour Dock Co. Eppleton Hall was sold to shipbreakers Clayton and Davie Ltd. for scrap in 1967 but was rescued – after having sat on a mud bank at Dunston for two years – by San Francisco Maritime Museum Trustee Scott Newhall. She was then rebuilt at Bill Quay during 1969 and modified to enable her to cross the Atlantic under her own steam. On 24 March 1970, six months and six days after setting sail from the Tyne, Eppleton Hall arrived in San Francisco Bay, where she remains to this day. The 56 year old tug, made only to sail on rivers, had made an epic 10,000 mile journey across two oceans. She is now the only remaining intact example of a Tyne-built paddle tug.

TWCMS : 2019.1482

***

Postcard, 1923

The Tyne tug Marsden was built in 1923 by J.P. Rennoldson & Sons Ltd., South Shields, for tug owners France, Fenwick Tyne & Wear Co. Ltd. In 1926 she departed these shores for a new life in Argentina, where she remained until being broken up in 2003, after an impressive 80-year career!

Marsden was a sister ship to the Tyne tug Hendon, built in 1924 by Rennoldson and broken up at Bo’ness on the Firth of Forth in 1966.

TWCMS : 2022.182

***

Case 13

Ship’s bell, HMS Kelly, 1938

This bell is the last surviving part of HMS Kelly, one of South Tyneside’s most famous warships. Built at Hawthorn Leslie’s Hebburn shipyard in 1939, HMS Kelly was brought into service just 11 days before the start of the Second World War. She suffered a turbulent start to her career, surviving damage from sea mines, a collision with HMS Gurkha and, in May 1940, attack from E- boats and bombers in the Battle of Norway. On all of these occasions she survived. Her luck finally ran out in 1941 when she was sunk in the Mediterranean during the evacuation of Crete. The bell, however, had been removed while she had been undergoing repairs at Hebburn, prior to the warship’s ill-fated voyage.

The Kelly has always been the source of immense local pride. It was widely acknowledged that it was the exceptional quality of the Kelly‘s design and the workmanship of those who built her that enabled her to survive as long as she did. The story of HMS Kelly was the inspiration behind the 1942 film, In Which We Serve starring Noel Coward and John Mills.

Acquisition made possible by a grant from the Preservation of Industrial and Scientific Material (PRISM) Fund.

TWCMS : 2010.3210

***

Ash tray from HMS Kelly, 1939

This copper ash tray features the ship’s badge of the famous Hebburn-built destroyer HMS Kelly. The donor’s father rescued this item from HMS Kelly when she returned to Hebburn for major repairs in 1940, following extensive damage inflicted during the Battle of Norway in May of that year.

TWCMS : 2022.85

***

Arthur Coote Memorial Scholarship certificate, 1960

Arthur Coote served an apprenticeship in the Dunbarton shipyard of Denny & Company before coming to work for Andrew Leslie at his Hebburn shipyard and marrying Leslie’s adopted daughter. On 1 January 1864 Leslie took Coote into partnership, offering him a third share in the business in return for £20,000. Around 1867 Coote’s share was increased, making him a half partner in the shipyard and estate.

Arthur Coote was a major figure in the company’s history, as it was he who brokered the partnership with the locomotive and marine engine builder R. & W. Hawthorn of Newcastle in 1885, a year after founder Andrew Leslie had retired.

In the late 1950s Arthur Coote’s great grandson Robin Gray served his time at Hawthorn Leslies’ Hebburn Shipbuilding Yard and would go on to become the yard’s Shipbuilding Director.

This certificate was awarded in 1960 to 17 year old apprentice tracer Marjorie Anderson.

TWCMS : 2021.118

***

Case 14

Retirement

Many shipyard workers left school age 15 and went straight into the yards, perhaps working initially in the time office or the general store before beginning to serve their time as apprentices from the age of 16.

Employment in the shipbuilding and ship repair industries could be unreliable, dependent on the volume of work in each yard at any given time. In quiet times workers would be paid off. Because men were taken on and let go so frequently, many ex-shipyard workers will tell you that they “worked in all the yards on the river” as they went from yard to yard in search of jobs.

A lucky minority stayed put and were kept in employment even when times were slack. Known as the “Royals”, they were the most experienced and reliable workers, who knew their yards like the backs of their hands, sometimes having served their time there and worked there all their adult lives.

Some yards kept workers on the payroll long after the conventional retirement age. When King George VI and Queen Elizabeth met shipyard workers at Hawthorn Leslies at Hebburn in 1943 they met the yard’s oldest employee, shipwright John Taylor, who was nearly 90 years old.

Retirement was a big occasion, when workers laid down their tools and reflected upon a life spent in the industry, upon very many ships built and/or repaired, the many friends made (and tragically sometimes lost through fatal accidents) and looked forward to a well-earned rest – which all too often was tragically cut short because of the long term effects of exposure to dangerous environments and materials.

***

Retirement presentations

1 This cartoon was drawn by Harry Bennet, the Gate Man at Brigham & Cowan’s ship repair yard in South Shields. The subject, wearing a checked brown suit and trilby hat, is Bob Fowler who retired from Brigham’s as the Stores Manager in December 1977. In the cartoon, Bob thinks his retirement gift will be a car, but it is in fact a skateboard inscribed with “Flyer”. Bob’s family commented, at the time of donation, that “The ‘Flyer’ is leaving the shipyard early, normally with the tacit approval of the Gate Man. The Gate Man manned the gates of the shipyard to ensure among other things no one left the shipyard before the designated time”. Bob Fowler served his time as an apprentice plater with Palmers Shipbuilding & Iron Co. Ltd., Jarrow, 1927-1931, before coming to work at Brigham & Cowans after Palmers went into receivership.

Donated by Marilyn Haines (née Fowler), the only child of Bob and Winnie Fowler.

TWCMS : 2022.98

2 Pocket watch, presented to John Curry by the Workmen and Staff of the Mercantile Dry Dock Co. Ltd., Jarrow, upon his retirement in 1919.

TWCMS : 2021.90

3 Rolex wristwatch, presented to John W. Herriott by the Directors of John Readhead & Sons Ltd., South Shields, upon his retirement on 31 December 1949

Loan: Peter Drew

4 Retirement presentation to Readheads employee William Howard, 28 September 1962.

TWCMS : 2022.22

5 The retirement of coppersmith Don Curry (3rd from left, holding a tankard). Middle Docks & Engineering Co. Ltd., South Shields, about 1980 or ’81

TWCMS : 2021.97

6 Retirement party for Tommy Houlsby, Head Foreman Shipwright at Middle Docks, South Shields, 1981. L to R: Paul Connelly, Alan Burrell, John Anderson, Tommy Houlsby, Neil Black, George Crooks, Alan Brennan (all shipwrights).

TWCMS : 2022.229

***

Long service presentations

Long service presentations were an occasion for yards to honour the experience and dedication of their longstanding employees, and for the recipients to take pride in their achievements over long careers. Inscribed wristwatches were a common long service gift from employers.

1, 2 and 3 Peerex wristwatch, presented to welder Anthony Carr in 1958 by John Readhead & Sons Ltd., for 25 years’ service. Anthony had served his time as a riveter, but retrained as a welder when riveting was declining. He is one of the 168 men pictured in the black and white photo, each of whom had given 25 years or more continuous service at Readheads, amounting to over 5,000 years in total!

TWCMS : 2022.146, 2022.149.1, 2022.150

Loan: Eleanor Mulley

4 Bulova wristwatch, presented to caulker/burner Edward Pippin by Brigham & Cowan Ltd., for 25 years’ service.

Loan: Eddie Pippin